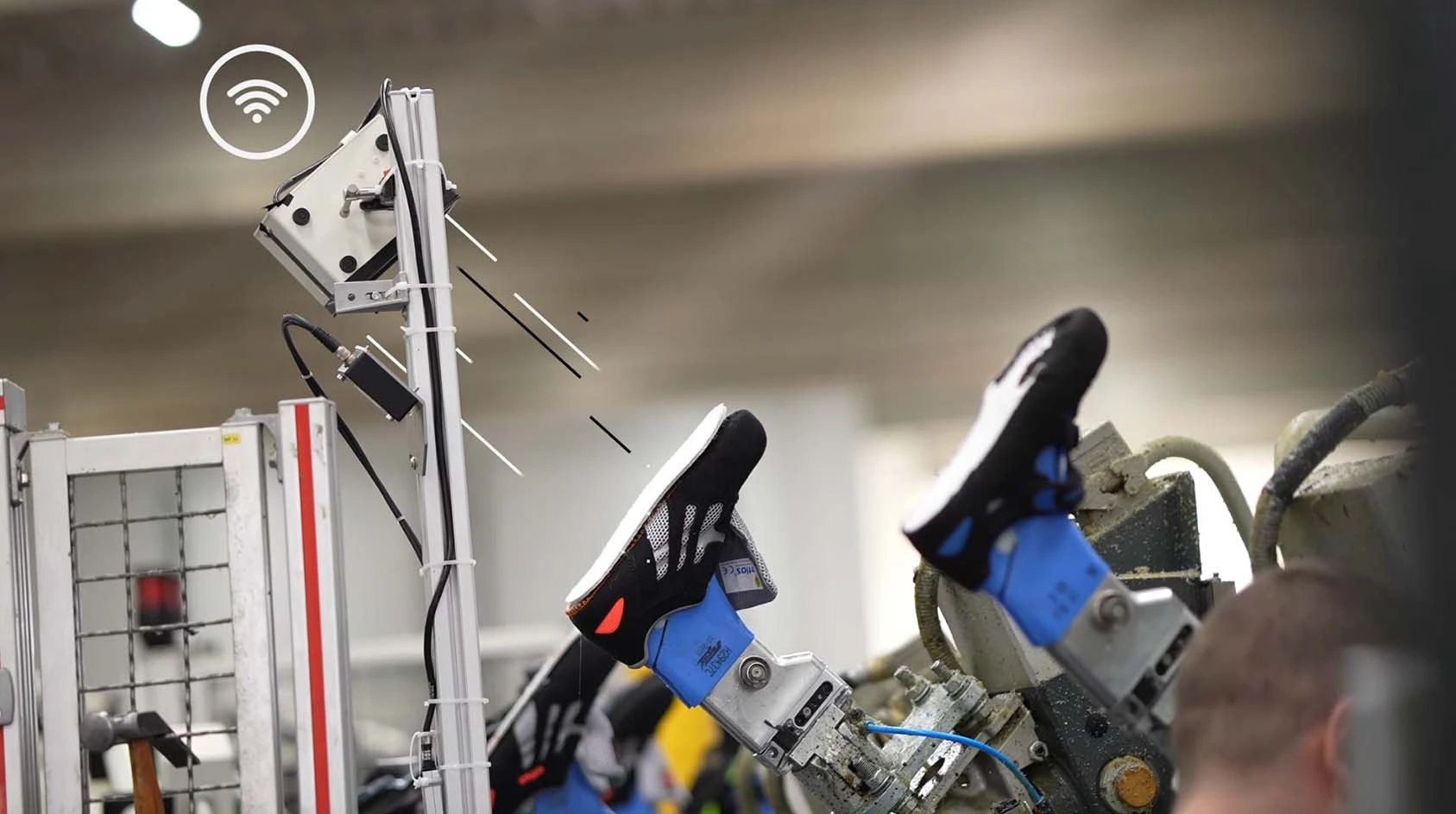

Together with Snap GmbH, Europe's leading manufacturer of safety shoes was able to take the next step in quality assurance: The production at ATLAS® in Dortmund is now even smarter thanks to the new AI-based inspection system OBAIS, which stands for "Optical Business AI Solution" and entails fully automated optical pattern recognition. During production at ATLAS® OBAIS scans the shoe soles and automatically detects the product condition during the surface inspection. This automates and optimises an important step in ensuring the highest quality. ATLAS® and Snap GmbH agree: Artificial intelligence is one of the keys to modern, efficient production in the future.

ADVANTAGES AT A GLANCE:

Artificial intelligence recognises errors that the human eye does not detect

and is constantly evolving

Automated quality assurance & better result quality

Relief for the employees in production

Increase in quality and customer satisfaction